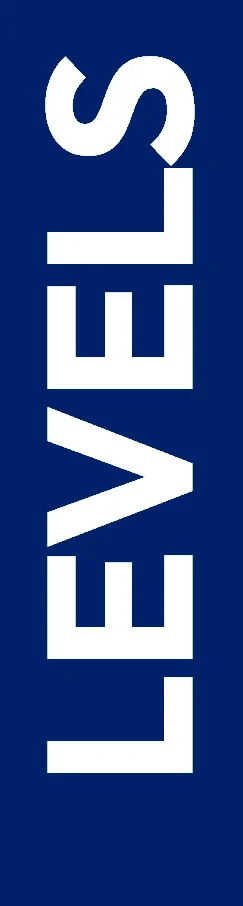

The simplified process ensures you can place your order in minutes, leaving you with more time to focus on other priorities.

Share your assignment specifics, including subject, deadline, and any special instructions.

Receive a personalised quotation depending on urgency. Pay securely to kick-start your project.

We deliver on time, allowing unlimited free changes until you’re 100% satisfied.

Our academic specialists are well-versed in CMI’s leadership frameworks, notably quality management at Level 6. They understand how to link assignments with the learning goals, ensuring your work fulfils all CMI criteria. From complicated themes like TQM (Total Quality Management) to Six Sigma, our writers craft each paper to perfection.

We pride ourselves on producing 100% unique assignments. With our strong anti-plagiarism policy, you’ll never need to worry about duplicated work or academic integrity breaches. Plus, we write everything without AI technologies, so your assignment displays a human touch matched to your writing style.

Tight deadlines? No problem! We understand the strain of academic timetables; thus, we promise on-time delivery—early if possible—so you have time to examine your work before submission.

We care about your pleasure. If any section of your project requires altering, we provide limitless free revisions. Collaborate directly with our professionals to fine-tune your project and guarantee the outcome surpasses your expectations.

At CMI Assignment Helper UK, we provide economical and high-quality assignment writing services for the CMI Unit 609 Leading Quality Management Level 6 course. Our staff of specialist writers has a strong grasp of the course subject and can give you well-researched and well-written assignments that will help you earn a high mark. We recognise that students typically have restricted budgets, which is why we provide our services at cheap costs. We also give discounts and special deals to our customers to help them save money.

In this part, we shall present various assignment tasks. These are:

Quality management is necessary for any business or organisation since it guarantees that the goods or services provided by the organisation meet or surpass the customers’ expectations. Over the years, there have been many various viewpoints and schools of thought on how best to approach quality management. In my answer, I will critically explore these organisational ways of quality management from multiple viewpoints and schools of thought.

It may be claimed that Lean Six Sigma is the management philosophy, including ideas of Lean and Six Sigma. Its purpose is the removal of any form of waste and boosting its efficiency, while Six Sigma seeks to eliminate variance and build quality. Lean Six Sigma depends on data and strives to discover and resolve laws in both processes, goods, or services.

Critics of Lean Six Sigma believe that it is too strict to apply to all enterprises. This helps it acquire advantages in the short term instead of a lengthy duration.

ISO 9001 is a standard that establishes a quality management system with which to assist an organisation in attaining the success and improvements of its quality management system. ISO 9001 incorporates standards in areas such as customer satisfaction, continuous improvement, and worker engagement in the quality management process.

Critics believe that it is overly bureaucratic for certain businesses, that it is unsuitable for all organisations, and that, by extension, ISO 9001 may not be successful in organisations without possessing a culture of continuous development.

Kaizen is a Japanese management concept focusing on constant improvement. Kaizen stimulates the active engagement of workers to identify and solve issues related to improving processes, goods, and services. Its emphasis on minimising waste and striving for excellence is comparable.

Critics claim that Kaizen may not be generalisable to all businesses, particularly those that demand a more formal approach to quality management. Kaizen is unsuccessful in firms with no deep culture of continuous improvement.

Quality management within organisational contexts is a complex and multi-dimensional process that entails various factors that can impact its effectiveness. Multi-dimensional issues are those that have multiple factors or dimensions that affect their outcomes. Here are some examples of multi-dimensional issues that can impact quality management within organisational contexts:

Multi-dimensional challenges will influence quality management, which is particularly significant in the organisational environment. Organisations have to consider carefully such challenges and consequently come up with solutions to handle the element efficiently. Effective quality management is not feasible if such concerns are overlooked; it leads to failure, affecting performance, reputation, and customer happiness. Thus, it is vital to grasp the relevance of multi-dimensional difficulties and take proactive actions to solve such challenges to generate good outcomes in quality management.

Create a system for managing quality: An organisation’s processes and procedures for management and improvement would be described in a QMS. Because a well-designed QMS guarantees that all processes are in line with the organisation’s goals and that resources are available to accomplish those goals, it helps make the organisation’s aims a reality.

Determine the key performance indicators. KPIs are the measurements that assist a company in assessing its performance about its objectives. The company may track its progress towards achieving strategic goals and, if needed, make modifications to fit with the intended result by identifying the appropriate KPI.

Put processes for continuous improvement into practice: The goal is to continuously enhance procedures, services, and goods. To accomplish strategic goals, a business implements continuous improvement procedures to identify and eliminate inefficiencies, which leads to an increase in quality.

Educate and Develop Workers: Employees are a key component in quality management. It is straightforward for a business to think about providing its staff with thorough training and development so they have the skills and information needed to apply quality management methods.

Develop a Culture of Quality The practice of quality management is promoted by a quality culture. Employees accept responsibility for quality when there is a quality culture in place and the company works together to achieve strategic goals.

Suggestion: Operational Level Quality Management

Executive Overview:

A thorough strategy for operationally leading quality management is presented in this proposal. The proposal seeks to define the essential elements of a successful quality management system and provide a structure for putting these elements into practice within a company. By adhering to this framework, businesses may make sure that their goods and services satisfy consumers, fulfil legal requirements, and enhance the general calibre of their operations over time.

Introduction:

An essential component of every organisation’s success is quality management. It entails the methodical procedure of guaranteeing that goods and services fulfil or surpass consumer expectations and adhere to legal mandates. All facets of activities should include quality management; it is not only the duty of the quality department. A framework for operationally leading quality management is presented in this proposal.

Commitment of Leadership: The organisational leadership group must commit to quality management as a fundamental principle. A quality management system’s development demands proper resources and assistance towards its upkeep.

Customer Focus: The company has to have a grasp of the customers’ wants and expectations. Such information will aid in informing the product and service development, manufacturing, and customer service components of the firm.

Process Approach: A quality management system must be regarded as a collection of interconnected processes that together contribute to the intended outputs. All essential processes should be identified and mapped with continual improvement.

Continuous Improvement: Continuous improvement is a property of a trustworthy quality management system. The company should regularly assess the processes, products, and services to create opportunities for improvement and then make adjustments if required.

Evidence-Based Decision Making: Decisions are made utilising facts and evidence rather than intuition or personal experience. The company gathers data for the examination of its processes for better decision-making.

Employee Involvement: All workers must be engaged in the quality management process. They need to be orientated on the concepts of quality management and inspired to take part in activities of continuous improvement.

Instil quality and continuous improvement concepts into work so that experts can pursue the same consistently. Through extended periods of intense efforts, it has been recognised that processes involving learning and growth without a little abatement are essential. Here are some methods by which people and teams may be aided in this process:

Experience the difference our CMI assignment help service provides from students voices.

O

Olivia

The CMI Assignment Help service provided me with exceptional support for my Level 6 coursework. Their deep understanding of strategic management and leadership principles made it easier to grasp difficult concepts. Thanks to their professional service, I was able to submit high-quality work and improve my grades significantly.

L

Lucas

Thanks to this assignment help service, I successfully completed my CMI Level 6 coursework with confidence. Their expert guidance, clear explanations, and commitment to quality made all the difference. A fantastic service for anyone pursuing advanced CMI qualifications!

E

Ethan

This service provided timely and professional support for my CMI Level 6 assignments. Their deep understanding of strategic leadership and management principles helped me excel in my coursework. Highly recommended for aspiring leaders!

C

Charlotte

The assignment help service was an absolute game-changer for my CMI Level 6 coursework. Their attention to detail and practical approach to problem-solving made my assignments stand out. Highly recommend it to anyone in management studies!

W

William

The team provided exceptional assistance with my CMI Level 6 assignments. Their ability to simplify advanced concepts while maintaining high academic standards was impressive. I couldn’t have achieved such great results without their help!

E

Emily

This service transformed my experience with CMI Level 6 coursework. The assignments were well-structured, with clear explanations and relevant examples that simplified complex topics. Highly recommended for advanced management learners!

Professional, reliable, and guaranteed satisfaction in 3 steps.